Rychlé informace

Stav: Nový

Napětí: 220V / 380V

Rozměr (D*Š*V): přizpůsobený

Hmotnost: 3500 kg

Certifikace: CE ISO

Záruka: 2 roky

Poskytovaný poprodejní servis: K dispozici je podpora třetích stran v zámoří

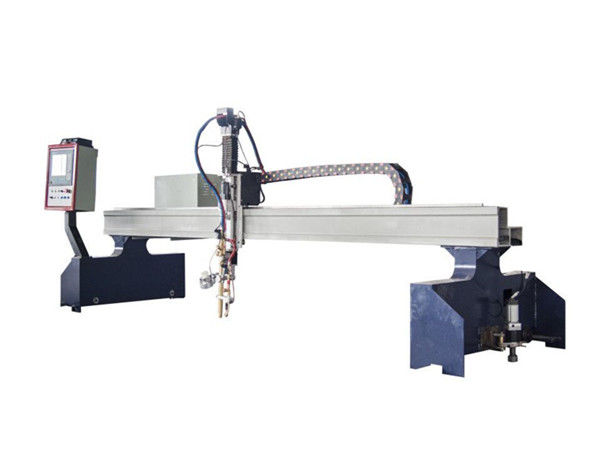

Typ: Portálový typ

Barva: Přizpůsobitelné

Funkce stroje

o Použitím vysoce přesné lineární vodicí lišty a oboustranného systému pohonu motoru pracuje stroj bezhlučně s vysokou rychlostí a vysokou přesností;

o CNC plazmové řezačky řady Hypertherm Powermax mají snadno použitelná ovládací rozhraní, podrobné informace se zvýrazněnými tlačítky a snadno se učí a obsluhují;

o Stroje mají funkci automatického ukládání do paměti a obnovy, když je vypnuto napájení;

o Stroj je také vybaven automatickou regulací výšky hořáku s elektrickým obloukem, může automaticky nastavit vzdálenost řezání.

Parametry stroje

Modelka | U-PC 3060 Plazmový plamenový řezací stroj |

Velikost strojního řezání | 3000x6000mm (jiné velikosti jsou přizpůsobeny) |

Režim řezání | Plazma a plamen |

Tloušťka řezu plamenem | 5-150 mm uhlíková ocel |

Tloušťka řezu Hypertherm 200A | 60 mm teoreticky |

Motory a řidiči | Japonská Yaskawa nebo Panasonic |

Řezná rychlost | 0-3500 mm za minutu |

Přesnost polohování | 0,02 mm |

Přesnost řezání plazmou | 0,2 mm |

Napětí stroje | 220V |

Plazmové napájecí napětí Hypertherm 200A | 380V |

Převodovka | Vysoce přesné lineární vodicí lišty, ozubené a ozubené převody |

Z: automatická kontrola napětí oblouku | |

Kontrolní systém | FL řídicí systém |

Softwarová podpora | FASTCAM, AutoCAD atd |

Instrukční formát | G kód |

Plazmové napájení | USA Hypertherm 105A/ 125A/ 200A |

Hardwarová konfigurace řídicího systému

1) .MCU: ARM9

2). Počet pohybů os: Interpolace pohybu dvou os (lze rozšířit na tři osy)

3). Max. Řádky kódu: 150 000 řádků

4). Velikost jednoho řezacího kódu: 4 MB

5). Prostor paměti souboru :: Elektronický čip pro velkokapacitní paměť, 512 MB

6). Uživatelská paměť: 256 MB

7). Přesnost ovládání: ± 0,001 mm (milimetr)

8). Rozsah souřadnic: ± 99999,99 mm

9). Maximální pulzní frekvence: 250KHz; Maximální rychlost pohybu: 25m/s.

10). Možnost řešení času: 10ms

11). Napájení systému: DC +24V

12). Provozní podmínky systému: Teplota: 0 ℃ - +55 ℃; Relativní vlhkost: 0-95%.

13). Rozhraní: USB

14). Rám: Celková kovová konstrukce, odolná vůči elektromagnetickému záření, proti rušení, antistatická

15). Speciální konfigurace: Dotyková podložka, 100m bezdrátový dálkový ovladač a kabelový ovládací box (volitelně pro celou řadu F2000)

16) .Podpora demo plynu, plazmy, prášku a simulace.

17). Klávesnice: klávesnice pro plošné spoje, rozhraní PS/2, tlačítko OMRON

Charakteristika řídicího systému

1). Alternativou je 45 kategorií různých grafik (včetně mřížkového vzoru), čipové části a díry.

2). Grafika má některé operace, jako je poměr, otáčení, zrcadlení.

3). Grafiku lze řadit do maticových, interakčních a skládaných režimů

4). Podle tloušťky plechu je řezná rychlost automaticky omezena rychlostním limitem v rohu, což účinně zabraňuje popálení.

5). Přepínač metrického systému/ systému imperia

6). Ocelovou desku lze nastavit podle jakékoli ocelové strany.

7). Souřadnicový systém lze přizpůsobit tak, aby podporoval dvojrozměrné souřadnice všech osmi druhů.

8). Všechny typy vstupních a výstupních portů a počet lze přizpůsobit (normálně otevřené nebo normálně zavřené)

9). Zálohování systému a parametrů, aktualizace systému online

10). Čínský / anglický (včetně japonštiny, ruštiny, francouzštiny a dalších jazyků) souborový systém a nabídku lze přepínat pouze jedním klíčem.

11). Vyberte řádek a sloupec ručně.

12). Podporujte řezání hran a ofsetové řezání.

13). Automaticky si pamatujte pracovní situaci a poslední řezný bod při vypnutí.

14). Dynamické / statické znázornění procesu, přiblížení / oddálení grafiky, dynamické sledování mezního bodu ve stavu přiblížení.

15). Nastavte různé administrátorské oprávnění a odpovídající heslo k ochraně zájmů manažerů.